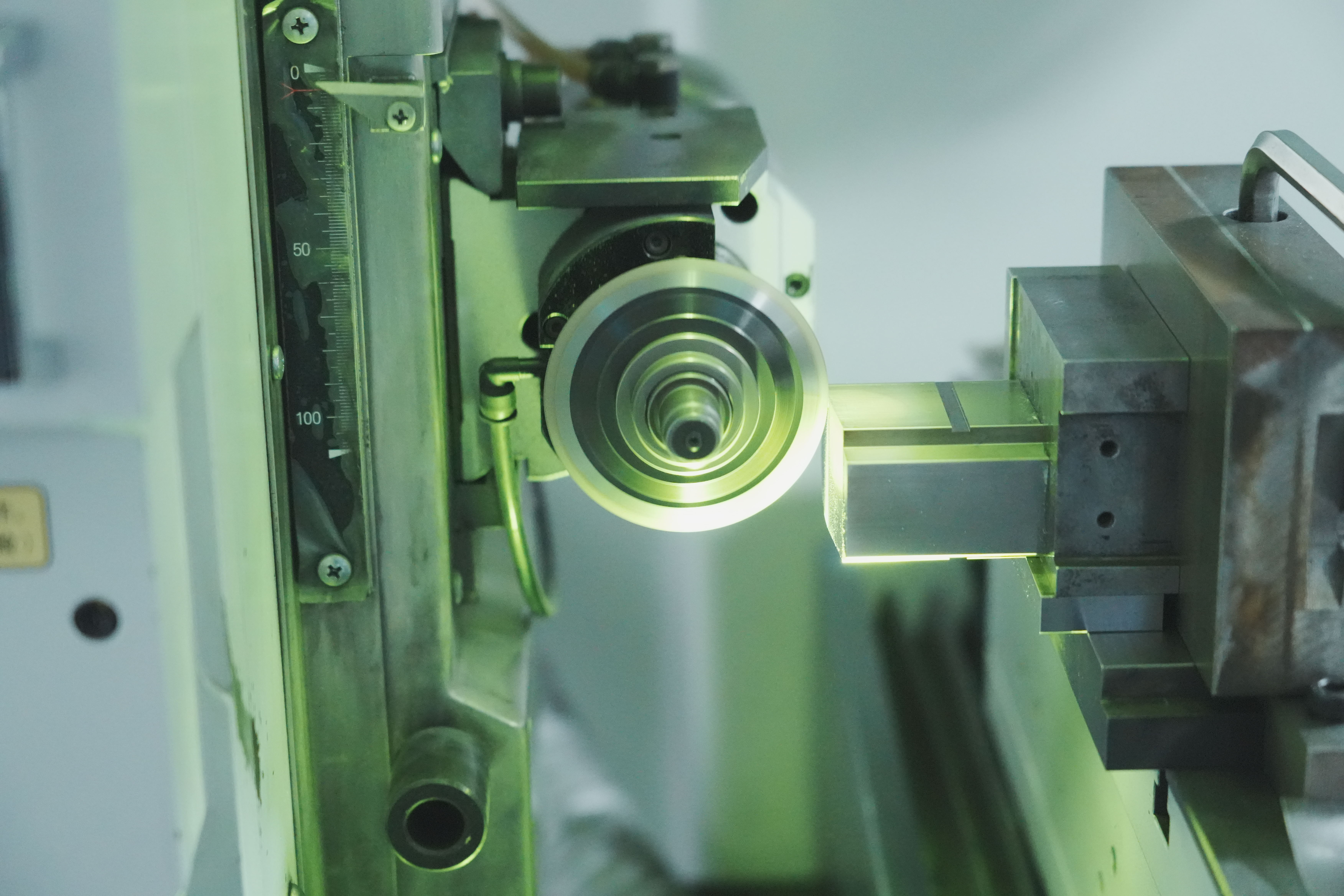

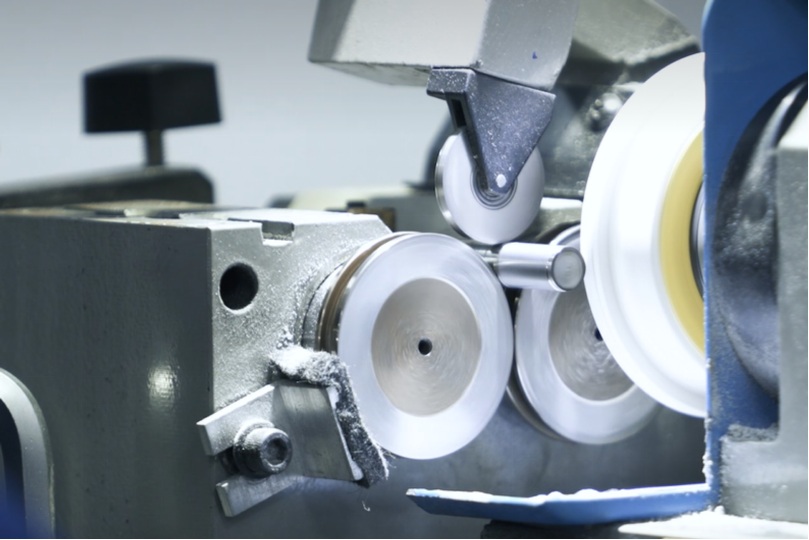

Achieving the desired surface finish and dimensional accuracy is crucial in manufacturing and precision machining.

Various techniques are used to achieve desired surface finishes, dimensional accuracy, and functional characteristics of multiple components.

Four standard methods for refining surfaces are grinding, honing, lapping, and polishing.