Kunshan Guozheng Precision Mold Co.,Ltd

Add: No.396, Dujia Road, Zhoushi Town, Kunshan City

Email: info@kokusei-seimitsu.com.cn

Tel:+86 0512-57171088

Cost

Materials

Quality

50+ metals

130+ High precision Machines

20+ surface finishes

Tolerance: 0.005 mm

ISO 9001 2015

ISO 2678

IQC-IPQC-FQC

Online services

Quick processing

Free repair

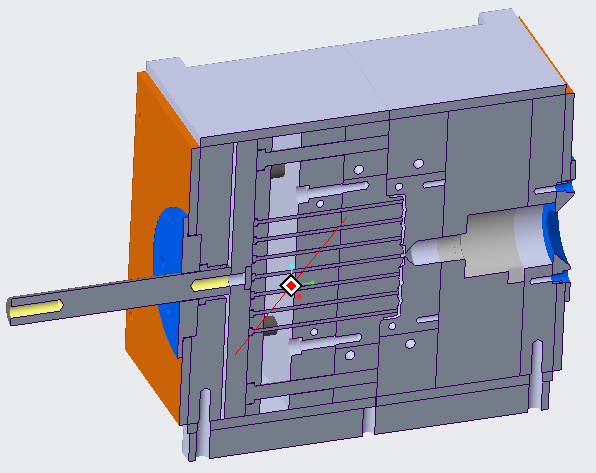

Tool Steel

Bearing steel

Die steel

High speed steel

Tungsten steel

Manganese steel

Molybdenum steel

Tungsten chromium steel

Heat treatment

Grinding

Honing

Polishing

EDM texturing VDI3400

Painting

Laser Marking