Kunshan Guozheng Precision Mold Co.,Ltd

Add: No.396, Dujia Road, Zhoushi Town, Kunshan City

Email: info@kokusei-seimitsu.com.cn

Tel:+86 0512-57171088

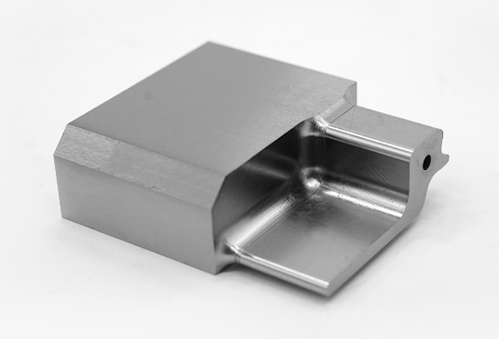

Tolerance range:±0.002

Surface roughness: Ra0.2

Workpiece size: 200*300*400mm

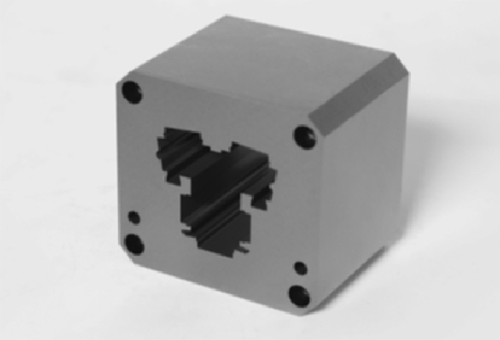

Tolerance range:±0.002

Surface roughness: Ra0.2

Workpiece size: 200*400*550mm

Tolerance range:±0.02

Surface roughness: Ra0.8

Workpiece size: 200*300*400mm

EDM Machining capacity | ||

| General Capabilities | Sinker Electrical Discharge Machining Wire Electrical Discharge Machining Small Hole Drilling EDM | |

| Equipment Capability | 4-Axis CNC Capabilitie | Tolerance: ISO 2768 Precision:+/-0.005 mm |

| Materials | Alloy Steel Carbon steel Stainless steel | Titanium Chromium-nickel-iron alloy Tungsten/Tungsten Steel |

| Additional Services | CNC Machining Sinker EDM Plating | Heat Treatment Testing Dimensional Inspection |

| Production Volume | Prototype Low Volume High Volume | |

| Lead Time | Job-by-job assessment Generally 2 to 3 weeks Expedited service available | |

| Additional infomation | ||

| Industry Standards | ISO 9001-2015 | |

| Industries Served | Semiconductors Sensors Energy Technolog | Electron and electron mic roscopes Optical Components Oil and Gas |

Tool Steel

Bearing steel

Die steel

High speed steel

Tungsten steel

Manganese steel

Molybdenum steel

Tungsten chromium steel

303

304

316L

2205 Duplex

17-4

15-5

416

420

430

440C

301

Titanium Grade 2

Titanium 6Al-4V

6061-T6

5052

1060

3003

4130

4140

5083

6082

5A12

7075 T651

5052

2024

1100

3004

5754

6063

7050

5A02

Brass C360

Brass 260

C932 M07 Bearing Br

Copper

Copper H62

Copper H65

Copper H70

Copper H80

Copper H90

Copper alloy special